Why Expanders Are Critical For Efficient Oil Recovery In Solvent Extraction Plants

A realization in the heart of a plant

Standing inside a buzzing solvent extraction plant for the first time, Rajesh Kumar, a plant manager, was struck by a single observation. The facility operated smoothly, yet he couldn’t help but notice the losses in oil recovery from the extraction process. Despite years of optimization, inefficiencies persisted, and the numbers didn’t lie. A consultant’s suggestion to introduce an expander seemed straightforward but revolutionary. After installation, the plant’s oil recovery rates soared by over 20%, cutting losses and boosting profitability significantly. This transformation highlighted the crucial role expanders play in solvent extraction processes, making them indispensable for modern operations.

For industries involved in solvent extraction, understanding the value of expanders is vital. Let’s explore how these machines contribute to efficient oil recovery and why they are critical for optimal plant performance.

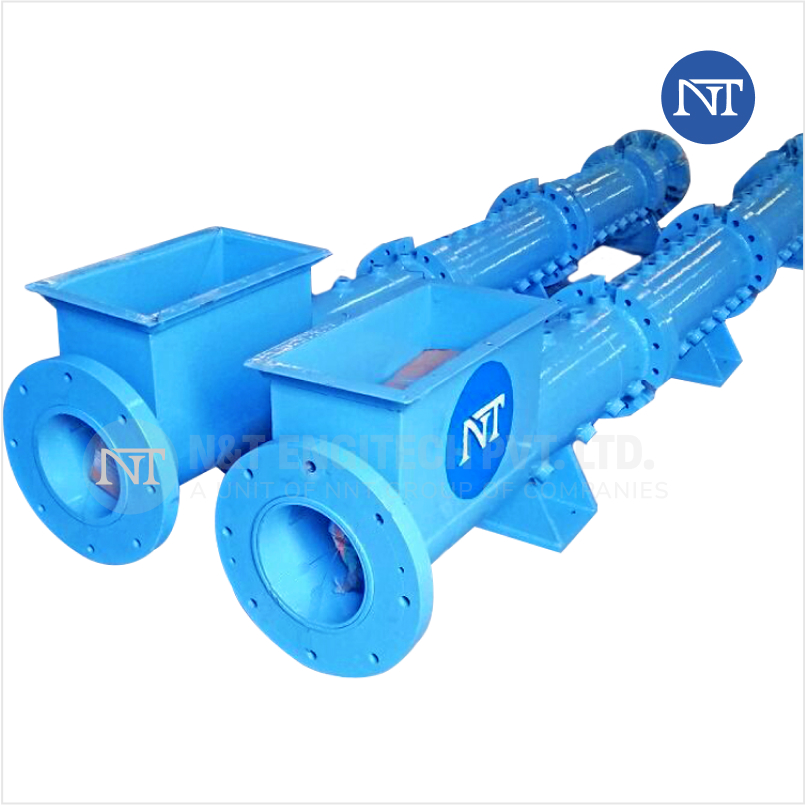

What are expanders in solvent extraction?

An expander is a specialized piece of equipment used in the preparation phase of the edible oil refining process The material compacts into porous, extruded shapes with an increased surface area, offering efficiency of solvent penetration. The mechanical and thermal treatment improves the solvent solvency for the extraction of maximum possible oil from the feedstock, thus involving higher rates of recovery.

Want to dive deeper into the working of expanders?

How does an expander enhance oil recovery in solvent extraction?

Expanders enhance oil recovery by:

- Increase porosity: The preparation of a more porous structure provides easy access of the trapped oil to the solvent.

- Residual oil content: Materials that come out from the expander possess lower residual oil content after extraction.

- Good penetration: The uniform shape and structure ensure uniform penetration of the solvent.

- Lowering solvent usage: Efficiency increases decrease the amount of solvent needed, hence saving money and the environment.

Why expanders are a game-changer

1. Improved oil recovery rates

Studies have found that expanders are capable of improving oil recovery by 15-20%. In a soybean solvent extraction plant, for example, residual oil in meal can be reduced from 1.5% to 0.7% through the inclusion of an expander (Journal of Oilseeds Research).

2. Enhanced efficiency in solvent extraction plants

Optimized oil recovery is not about numbers—it’s a question of sustainability and affordability. Solvent extraction plant manufacturers now emphasize expanders as a core component to achieve these benefits.

- Stat: The global market for efficient solvent extraction systems is estimated to grow at a CAGR of 4.5% during the period 2023-2030 (Grand View Research).

3. Reducing energy consumption

Expanders warm and condition the material, reducing downstream process energy requirements. This is particularly crucial for energy-intensive processes.

- Fact: Properly integrated expander reduces overall energy consumed in the extraction process by up to 12% (Global Energy Insights).

The role of expanders in edible oil refining process

Refining plant of edible oil relies on the quality of feed on a regular basis for optimum result. Conditioning the raw material and maximizing the recovery of oil during the process of extraction, expanders directly impact the efficiency and quality of the refined oil.

- Example: During the processing of sunflower seeds, an expander reduces the possibility of clogging during refining, offering smoother processes.

Challenges addressed by expanders

1. Variability in raw materials

Quality of raw material can vary depending on differences in moisture level, seed variety, or contamination. Expanders standardize the feedstock, and it becomes easier for solvent extraction plants to run efficiently.

2. Sustainability goals

Plants are increasingly being put under pressure to be more eco-friendly. By reducing the consumption of solvents and energy, expanders help plants comply with environmental regulations.

- Insight: Expanders are being utilized by solvent extraction plant manufacturers to obtain green certification.

3. Residual oil losses cost

Residual oil in the meal is a producer loss. Expanders reduce this loss, leading to higher yields and profitability.

Key Features of Modern Expanders

1. Automation

Large expander extruder manufacturers today have advanced automation systems integrated into their machines, enabling precise control of temperature, pressure, and feed rates.

2. Low maintenance and durability

New expanders are built to last, reducing downtime and maintenance costs for operators.

3. Customization

From rapeseed to soybean, expanders can be optimized to the different feedstocks in order to optimize efficiency regardless of material.

Real-world impact of expanders

Case study: a soybean plant transformation

A soybean processing facility in India partnered with leading solvent extraction plant manufacturers to integrate expanders into their operations. Before installation, the plant struggled with high residual oil content in the meal, leading to substantial losses. Post-expander implementation, the plant saw:

- Residual oil reduction: From 1.4% to 0.6%.

- Increased oil recovery: Yield improved by 18%.

- Cost savings: A 10% reduction in solvent usage saved the plant $500,000 annually.

The future of expanders in solvent extraction plants

Industry trends

- Thrust on sustainability: As more and more environmental issues arise, expanders are turning into the key driver of attaining green production processes.

- Design innovation: Expander extruder producers innovate designs to accommodate more material types.

- Integration with IoT: Smart expanders with IoT power have real-time monitoring and predictive maintenance, reducing downtime.

Market growth

The international solvent extraction equipment market is projected to exceed $3.5 billion by 2030, with expanders being a key contributor to this growth (Market Research Reports).

Conclusion

Expanders have transformed the process of solvent extraction, increasing oil recovery rates, lowering operational expenses, and attaining sustainability objectives. For businesses that want to maximize their operations, collaborating with seasoned expander extruder manufacturers and solvent extraction plant manufacturers is the secret to success. These technologies are not merely technological; they’re about changing the way we recover oil.

How can you incorporate expanders in your business to realize their full potential?