How to Measure a Box for Dimensions: A Step-by-Step Guide

Intorduction

When it comes to packaging, shipping, or even just organizing your space, knowing how to measure a box for dimensions is crucial. This skill ensures you choose the right size box for your needs, optimize storage, and avoid unnecessary shipping costs. In this guide, we’ll walk you through the process of measuring a box step by step, ensuring you get accurate results every time.

Understanding the Basics: Why Measuring a Box Accurately Matters

Accurately measuring a box is more than just a simple task. It impacts several aspects of logistics, from selecting the right custom packaging materials to determining shipping costs. When you measure a box correctly, you can also avoid overpacking, which can lead to increased shipping fees, and underpacking, which may not adequately protect your items.

Tools You Need to Measure a Box

Before you start measuring, gather the right tools. You’ll need:

- A tape measure or ruler

- A notepad and pen for recording dimensions

- A calculator (optional, but useful for calculating volume)

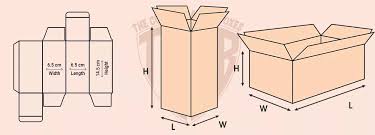

Step 1: Identify the Box Orientation

The first step in measuring a box is to identify its orientation. Determine which side of the box is the length, width, and height. Usually, the length is the longest side, the width is the shorter side, and the height is the distance between the top and bottom when the box is standing upright.

Step 2: Measure the Length of the Box

Place the box on a flat surface and start by measuring the length. The length is the longest side of the box, typically the front of the box. Use your tape measure or ruler to measure from one edge to the other, ensuring the tape measure is straight and not slanted, which could result in an inaccurate measurement.

Step 3: Measure the Width of the Box

Next, measure the width, which is the side perpendicular to the length. Again, ensure that the tape measure is straight. Record this measurement in your notepad.

Step 4: Measure the Height of the Box

Finally, measure the height of the box. The height is the distance from the top to the bottom of the box when it is placed upright. This is the most critical dimension if you are considering how the box will stack or fit into a specific space.

Step 5: Record the Measurements

Once you’ve measured the length, width, and height, write them down in a systematic order, usually length x width x height (LxWxH). This order is standard in most industries, especially in shipping and packaging.

Step 6: Calculate the Box Volume (Optional)

If you need to calculate the volume of the box, multiply the length, width, and height measurements together. The result will give you the box’s volume, usually measured in cubic inches or cubic centimeters.

Tips for Measuring Irregularly Shaped Boxes

Not all boxes are perfectly rectangular. If you have an irregularly shaped box, measure the longest point for each dimension. For example, if the box bulges out in the middle, measure from the widest points. This method ensures that you account for the entire space the box will occupy.

Common Mistakes to Avoid When Measuring a Box

- Not measuring at the widest points: Ensure you measure the longest and widest points, especially for irregularly shaped boxes.

- Using a flexible measuring tape incorrectly: Make sure the tape measure is straight and taut, as any bends can lead to inaccurate measurements.

- Forgetting to include box flaps: If your box has flaps that will be used in the final packaging, include them in your measurements.

How to Measure a Box for Shipping

Shipping companies typically use two types of measurements: actual dimensions and dimensional weight. Dimensional weight is a shipping calculation that considers the volume of the box to determine shipping costs. To measure a box for shipping:

- Measure the length, width, and height as described above.

- Multiply these dimensions together to get the cubic size of the box.

- Convert this number to the appropriate shipping dimensional weight based on the carrier’s guidelines.

Measuring a Box for Storage Solutions

When measuring a box for storage, consider the space you have available. Measure the internal dimensions of the storage space and compare them with the box’s dimensions to ensure a good fit. Also, consider how you’ll stack boxes, as the height becomes particularly important in these scenarios.

The Importance of Measuring Internal Dimensions

Sometimes, you may need to measure the internal dimensions of a box, especially if you’re concerned about how much it can hold. To do this:

- Open the box and measure the internal length, width, and height.

- Subtract the thickness of the box walls from your external measurements to get the internal dimensions.

How to Measure a Box for Custom Packaging

Custom packaging often requires precise measurements to ensure a perfect fit for your products. When ordering custom boxes, provide the manufacturer with accurate external dimensions. It’s also a good idea to account for any padding or inserts you plan to use inside the box.

Understanding Dimensional Weight for Shipping

Dimensional weight is a key concept in shipping. It’s calculated by multiplying the length, width, and height of a box and then dividing by a specific divisor provided by the shipping company. This calculation helps carriers account for the space a package occupies in relation to its actual weight. Always measure carefully to avoid unexpected shipping costs.

The Role of Box Dimensions in Cost Efficiency

Box dimensions directly impact cost efficiency in both storage and shipping. By selecting the right size box, you can minimize wasted space, reduce material costs, and avoid overpaying for shipping. Accurate measurements are essential to achieving these savings.

Using Box Dimensions in E-commerce

For e-commerce businesses, box dimensions are crucial. They affect shipping rates, inventory storage, and customer satisfaction. Providing accurate box dimensions ensures that customers know what to expect, reduces return rates, and helps maintain positive reviews.

How to Measure a Box with Handles or Cutouts

Boxes with handles or cutouts may require special attention. When measuring such boxes, ensure you measure the overall dimensions without excluding the handles or cutouts. This is especially important if the box will be shipped or displayed in a retail setting.

Comparing Internal vs. External Measurements

External measurements are usually more critical for shipping and storage, while internal measurements matter more when determining what will fit inside the box. Always clarify which dimensions are needed based on the context.

The Impact of Box Shape on Measurements

The shape of the box can significantly impact how you measure it. For example, cylindrical boxes require different measurement techniques, such as measuring the diameter and height, and then calculating the volume using the formula for the volume of a cylinder.

When to Use a Caliper for Measuring Boxes

In some cases, especially for small boxes or boxes with intricate details, a caliper may be more accurate than a tape measure. Calipers can provide precise measurements down to fractions of an inch or millimeter, which is essential in high-precision scenarios.

Customizing Box Dimensions for Special Projects

When designing or ordering custom boxes, consider any special requirements such as additional padding, dividers, or unique shapes. Provide these details along with your measurements to the manufacturer to ensure a perfect fit for your needs.

FAQs

How do you measure a box for dimensions?

Measure the length, width, and height of the box using a tape measure or ruler. Record the dimensions in the order of length x width x height.

What tools do I need to measure a box accurately?

You need a tape measure or ruler, and possibly a calculator for calculating volume.

Why is it important to measure a box correctly?

Accurate measurements help in choosing the right box size, optimizing storage, and reducing shipping costs.

Can I use a ruler instead of a tape measure?

Yes, a ruler can be used, especially for smaller boxes. However, a tape measure is more versatile for larger boxes.

What is dimensional weight, and why does it matter?

Dimensional weight is a shipping calculation that considers the volume of the box. It helps carriers charge appropriately based on the space a package occupies.

How do I measure an irregularly shaped box?

Measure the longest and widest points of the box to account for the entire space it occupies.

Conclusion

Measuring a box for dimensions is a straightforward yet essential task that plays a significant role in shipping, storage, and packaging. By following the steps outlined in this guide, you can ensure that you obtain accurate measurements every time, leading to more efficient use of materials, optimized shipping costs, and better storage solutions. Whether you are in e-commerce, logistics, or just organizing your home, knowing how to measure a box correctly will save you time, money, and effort.